Dyrhoff Ltd is pleased to announce that it has successfully achieved certification to the internationally recognised ISO 9001 Quality Management Standard and ISO 14001 Environmental Management Standard following an assessment by the British Assessment Bureau this month.

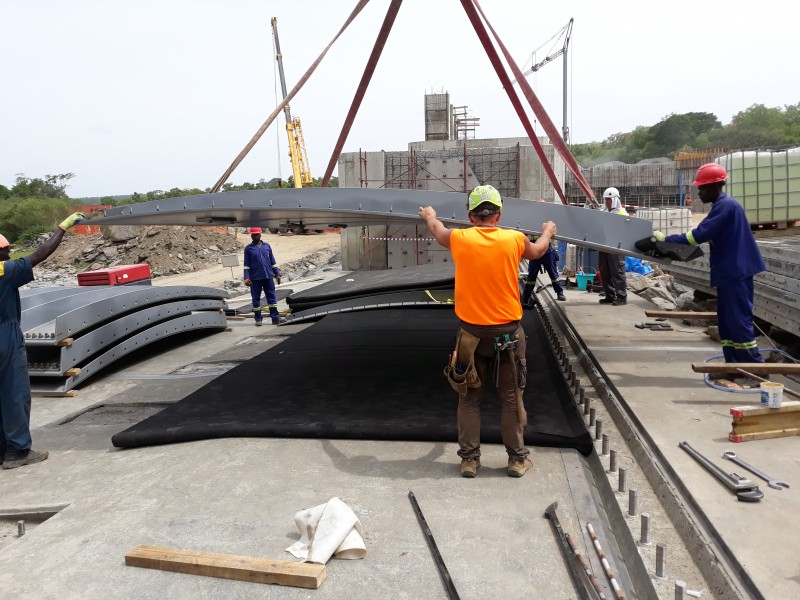

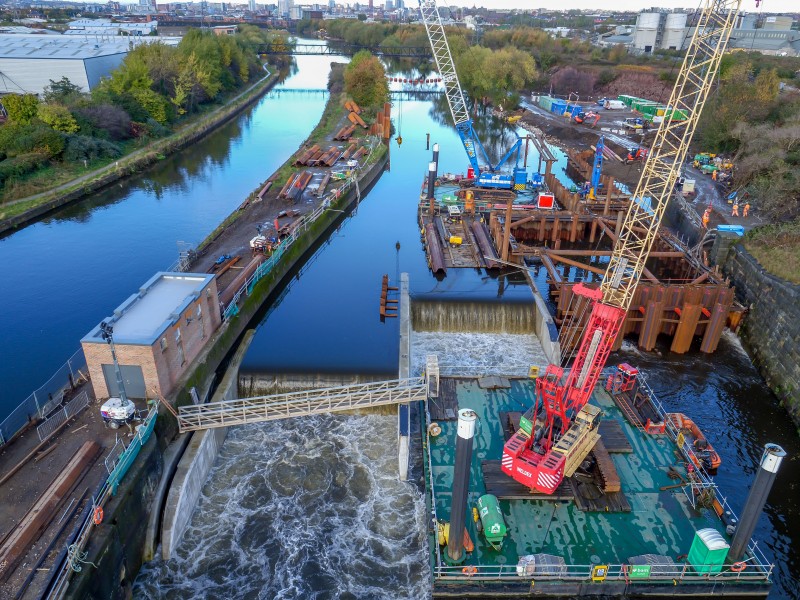

For 25 years, Dyrhoff has been a world leader in the design and supply of inflatable rubber dams and spillway gates. Over the last quarter of a century, the company has supplied over 150 systems across 4 continents.

Dyrhoff have an exclusive license to supply rubber dams conforming to the Sumitomo design and is the exclusive European agent for the Obermeyer spillway gate system. Their ISO 9001 and ISO 14001 certifications underlines the company’s seriousness and integrity in its engineering field, and actively demonstrates its ability to deliver quality and environmentally sound products and services, as verified by an independent third-party.

Each year, an independent assessment will be carried out by the British Assessment Bureau to ensure Dyrhoff continue to demonstrate it is meeting the requirements of both ISO 9001 and ISO 14001 on an ongoing basis. This rigorous assessment is backed by UKAS accreditation, which is supported by government.

ISO 9001 involves the implementation of a Quality Management System, which helps organisations to formalise processes, resulting in improved performance and – as a result – improved customer satisfaction. ISO 14001 involves the implementation of an Environmental Management System, helping organisations maintain an effective environmental policy and action plan to manage their impact on the environment.

The benefits of registration to ISO 9001 Quality Management Standard include:

- Streamlining an organisation’s procedures;

- Bringing consistency to an organisation’s product / service delivery;

- Reducing cost and rework;

- Improving an organisation’s management practices;

- Enhanced status;

- Competitive advantage;

- Lower insurance premiums.

The benefits of registration to ISO 14001 Environmental Management Standard include:

- Organisations are able to demonstrate their environmental credentials;

- Win more business;

- Achieve operational excellence;

- Reduce overall costs, overheads and wastage through the implementation of an environmental policy;

- Gives organisations a focus on proactive management;

- Ensure legislative awareness and compliance as a business.

Commenting on the fantastic achievement, Gabriel Topalian from Technical Sales at Dyrhoff said;

“In this industry, quality and a clear environmental mind-set is imperative. Achieving certification to ISO 9001 and ISO 14001 demonstrates our commitment to offering our customers the very best product and service as well as the assurance they are dealing with an environmentally sustainable company. We are delighted to become ISO certified, and look forward to the successes our achievements will bring throughout 2016 and beyond.”